There are many mounting options for electric trolling motors. If you are using a bow-mounted motor, I recommend using a quick-release bracket. This bracket is a piece of thick poly with a smaller block cut out of the center, and you bolt the smaller block to the boat and the larger outer frame to the trolling motor base.

If you are using a transom-mounted motor, I recommend an adjustable outboard motor bracket. Most of the outboard motor brackets attach to the transom of your boat with four heavy-duty bolts. In the middle of the bracket is a handle that you can set in three or four positions to change motor depth with ease.

Why would I want to use a quick release motor bracket?

I have three key reasons I would use a quick-release bracket. First, if you are taking your motor in for service, it will need to be completely uninstalled from your boat. Second, if I am taking the boat in for any other service, it discourages thieves from browsing your boat while in the lot overnight. Finally, if I am taking a non-fishing boat ride like a fourth of July fireworks show I like to lighten the boat up as much as I can.

The process for removing my motor is quite simple, with the electronics being the hardest part. I unplug the power, remove the transducer, disconnect the link ethernet cable, and unlock the motor. The motor is easy for one person to carry and stores well in the stowed position.

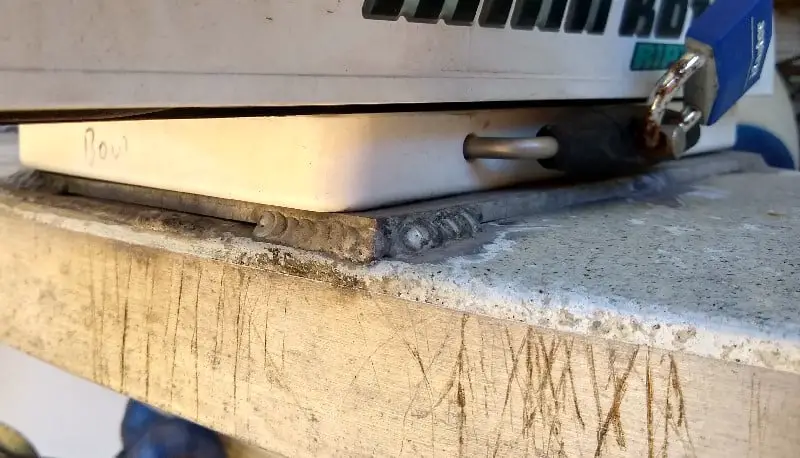

There are two main options that I am aware of for quick-release electric trolling motor brackets. The first option is the standard manufacturer mounting bracket. The bracket starts with a rectangular piece of poly material that has a smaller block of material cut out of the middle. The two pieces of poly fit tightly together with the small piece bolting to the boat and the large piece bolting to the motor base. A locking retainer bar slides through two holes to secure the pieces together and is firmly attached to your boat.

The second option for quick release is a mounting system that has interchangeable attachments. The Leelock system (link here to Leelock.com) consists of a base bracket that mounts the center position on the bow of your boat, and then you can lock in different assemblies. Some of the options are the traditional anchor nest, the anchor can, and trolling motor bracket.

I like the concept of this product, but I have two issues with my use situation. I use my trolling motor a lot, so I want a more permanent style mount. The second is that if I want to switch my type of fishing or need to anchor for an emergency like engine failure, I will need both an anchor and a trolling motor. If you are a more casual bow mount electric motor user, I would say this is the way to go. Also, you will want to have a power plug with easy access.

For a third option, Attwood makes a slide-on bracket that looks good. I have not used this bracket, so I am going on the installation instructions. The system includes a base plate that you mount to your boat and a slide plate that you mount to your motor. Included in the package are all the bolts that you need for the installation.

Why would I use an adjustable outboard motor bracket?

The main reason I would recommend an adjustable outboard motor bracket is for versatility. You can change out your trolling motors between gas or electric without a headache on an outboard motor bracket. When you use an electric trolling motor, they are normally easy to adjust the depth, but a gas motor is not so much.

Gas motors come in certain lengths, and the main way to adjust your motor up is with what they call shims. Shims are small pieces of wood that you can stack up to lift the motor up off the transom of your boat. Adjusting with shims is limited to the amount that you can move the motor mount clamps up safely. If you have a small lake boat, the sides can be quite low so an adjustable mount in the main position can compensate for a long motor shaft.

An outboard bracket has a small handle in the middle and can be repositioned easily when onshore or before the motor is installed. Adjusting the bracket after the motor is installed can be difficult because of the weight of your motor. For an electric trolling motor, the weight is minimal, so it is an easy adjustment.

Can I get a custom electric trolling motor bracket?

There are a lot of small welding shops that make products for boats. Many of these shops will make anything you want. You can walk into a welding shop; show them a picture, and they will make it up for you. I always work with people that do boat work because you know that they will have the equipment to do the work.

I have had a lot of custom items made for my boat and electric trolling motor. The last fully custom item I had made was a skeg extension to help with my tracking. I made an appointment with the welder so we could work on the project. I brought a cardboard model, and he produced a great piece. I would guess that if I walked in with a cardboard model of a mounting bracket, I would leave with exactly what I wanted.

Can I make a trolling motor bracket?

You can make a trolling motor bracket in your home shop. I have made a few different brackets to compensate for motor shaft length.

The first thing to consider is the weight and power of the motor need to match the construction and material used to make the bracket. For example, if you have a 35lb electric trolling motor a pressure-treated piece of 2” by 12” might work just fine but it will never work for an 8 hp gas motor.

I have used pressure-treated 2” by 12” with two pieces of angle iron to reinforce and mount the 2” by 12” to the transom of my small lake boat in the past. Adding a flat bar horizontal can be a great place to install carriage bolts and will add extra strength to the 2” by 12”.

For small bow mount electric trolling motors, I have seen a lot of different improvisations, I can only share what I saw, not the performance or safety. On a small no gas motor lake, I saw a boat with a boat trailer roller bracket bolted to the deck of the boat and a block of wood fastened to the bracket. I am not sure if the motor handle was modified to fit on backward, but the driver had a trolling motor arm extension and was running the boat quite well. I will add he was catching and I was only fishing.

Are there options for mounting my motor on a canoe?

There is one manufactured option for mounting your electric trolling motor on your canoe in the form of a flat metal bar with clamps. The flat bar has two thumb screw clamps on top so you can tighten it to the top rails of your canoe, then a block that extends up to mount your transom electric trolling motor.

I think this bracket could be modified to work for small bow mount motors by using two of them and attaching a 2” by 8” to create a mounting deck for your bow mount trolling motor.

If you have not purchased your canoe yet consider buying a canoe with a transom at the back made for a trolling motor.

Conclusion:

There are a few ready-made options for electric trolling motor options, with more coming to the market every day, but if you are mechanically inclined or can find a flexible welding shop to work with the options is limitless to fit your needs.