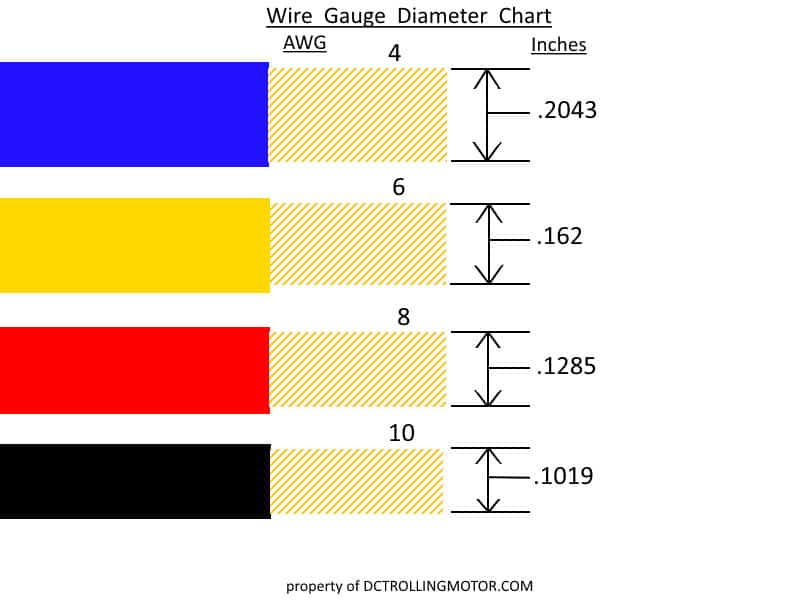

In most cases, the manufactures recommended wire is 8 gauge for most 24-volt systems and 6 gauge for a system of 20 feet or longer. To account for voltage-drop, heat, and current changes resulting from low batteries I recommend 6 gauge wires, and 4 gauge wires for over 15 feet. My additional reasoning for this recommendation is that your system will degrade between maintenance to remove corrosion and replace connectors.

I think to get the whole picture, we are going to need to start with a different question, and then we can answer the original question in detail.

Note: most links in this article are Amazon.com Affiliate links, see Affiliate Disclosure, thank you.

How many amps does my 24 volt trolling motor draw?

Most 24 volt trolling motors have a maximum amp draw of 56 amps. This draw is startup amperage for maximum speed. After the electric trolling motor has started spinning, the amp draw will go down. However, each motor is different so let us dig into the subject.

The main way to find how many amps your trolling motor draws is to look in the back of your manual. You can also look up product specifications on manufacturer websites, but this information can be buried in their site and hard to find.

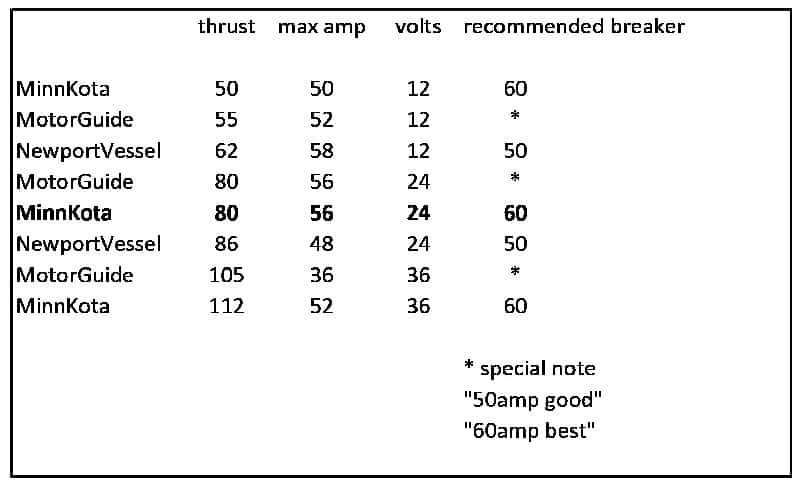

I went through the big three manufacturers’ information and generated a table. I created the table including the highest demand motors in each voltage so it would be more useful and give you an idea of how the thrust relates to amperage.

Table 1

My motor is a Minn Kota 80 lb Riptide 24 volt. If you look at the chart, it is right in the middle of my chart. You can see on the chart that the maximum amp draw for my motor is 56 amps, per hour.

Keep in mind this is manufacturer information, and they might want to be on the safe side of the numbers. I put the ammeter on my power cable while running my motor at full power, and it was lower, how much lower, I will leave it at lower, so we use the best wire per the information we have.

Electric current can also vary based on the load or resistance against the motor. This is why you need to check your propellor regularly for fishing line or weeds.

How do I calculate what gauge wire I need for my 24 volt trolling motor?

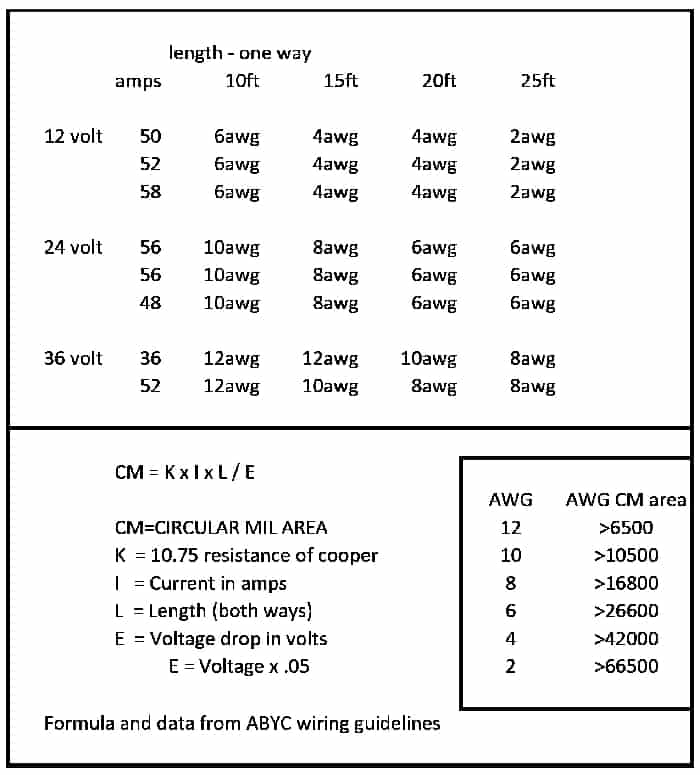

I went through all the information on the ABYC wiring guidelines, which are in line with the US Coast Guard Code, and got the formulas to generate a table. The leading manufacturer calls for a maximum of 5% voltage drop, but the standard tables are categorized at 3% or 10% voltage drop.

I did more research on electric motors, and it appears that a drop in voltage of more than 5% can cause damage to a standard electric motor. As a result, I had to build tables. If you wanted to use a standard table, you would need to use a 3% voltage drop table to avoid any chance of electric motor damage.

Table 2

I did the calculations and compared the numbers to the manufacturer’s information. The middle of the table wire gauge size matched exactly on the 24 volt motors, but the short length and the long length did not.

The formula generated a smaller gauge wire for the shorter length system connections and a larger gauge wire for the longer connections. From my observation, it appears that the manufacturer upsized the wire on the shorter lengths to be uniform with the trolling motor lead and to prevent a smaller wire from acting as a fuse which could cause a fire.

To be safe, always go up to the next size wire. (For example, if the chart calls for a 6awg, use a 4awg) If you go up in wire size, the worse that can happen is that it will cost you a little more money. If you undersize your wire, you could damage your motor, control board, or have a boat fire. None of the things I listed are a problem if you can swim, right?

We have another article with a detailed chart and more wire gauge information.

Click the image to see the price on Amazon.com.

What is the correct size circuit breaker or fuse for my 24 volt trolling motor?

If we go to table one in the last column, you will see a manufacturer-recommended breaker size, which is either 50 amp or 60 amp. The most important factor when choosing a fuse is not to allow more current through the fuse than the wire can handle.

You can go back to the table and see that if a wire is 10 gauge, it should be a 50 amp breaker/fuse, and if it is an 8 gauge wire or larger, you will use a 60 amp breaker/fuse. I would only use 8 gauge wire or larger so I can avoid using a 50 amp breaker/fuse completely.

Click here to read our review of Trolling Motor Batteries

Conclusion:

I have provided tables that I made from manufacture data and ABYC wiring standard formulas, but when in doubt, always use bigger gauge wire. Also, if you use a 3% voltage drop table, you will be safe. Lastly, never oversize your circuit breaker.

FAQ:

Q: What gauge wire is used for 24 volt trolling motor extension cable?

A: The correct combination of cable size and fuse rating will depend on the distance traveled by a current within the cables, as well as on whether they are exposed or in conduit runs. most trolling motor manufacturers include this information in their user manual, on their website, or you can find charts on component manufacturers like Blue Sea Systems websites.

Q: What gauge wire is used to connect an electric trolling motor to a battery?

The correct combination of cable size and fuse rating will depend on the distance traveled by a current within the cables, as well as on whether they are exposed, in conduit runs, or in a bundle. Check the table above and cross-reference it with your user manual.

Tip: It won’t hurt your system to purchase the next larger size wire.

Q: How many amps will my trolling motor draw?

A: The amount of current required by your electric trolling motor depends on the type, model, and thrust of the motor. As a generalization, an 80-pound thrust trolling motor’s max draw is 56 amps.

Q: What is a safe operating voltage for a 24-volt trolling motor?

A: Most 24-volt trolling motors will function well from 24 volts up to 27 volts, but you should confirm this with your user manual. More complex motors with more moving parts like the Minn Kota Ulterra are more voltage sensitive than basic motors like the Minn Kota Traxxis. Additional, running your motor at a low voltage is bad for your system because of increased amperage.

Q: Can I connect my 24-volt trolling motor directly to a deep-cycle battery?

A: Never directly connect your 24-volt trolling motor to a deep cycle marine battery Always add a breaker or fuse within 7 inches of the positive battery terminal for safety.

Q: How do I connect my trolling motor to a boat with no receptacle?

A: Using power distribution terminal blocks and ring terminals will provide stable connection points and still allow for your motor to be disconnected

References:

US Coast Guard Electrical Codes link below

https://ecfr.io/Title-46/pt46.7.183#se46.7.183_1340

ABYC E-11 electrical manual purchase page link below